Farason is capable of solving a wide variety of customer needs. We are a solution when end users want one primary interface. We provide integration with third party OEM production systems including safety, global E-Stops, data collection and programming handshakes

Our robotic systems utilize a combination of commercially available componentry and Farason designed tooling. Farason has integrated ultrasonic welders, 2D/3D vision technology, labelers, fillers, banders, metal detectors, and numerous other application specific devices

Farason's expertise in flexible feeding is on par with the best companies in the world. Vision guided robotic unscrambling technology serves large and small product mixes with minimal to no changeover

Both our on-site machine shop and our numerous qualified vendors ensure that every piece of equipment is designed and built to match customers specifications.

Our world class team of designers have amassed decades of experience creating custom machinery and systems that can meet even the most rigorous standards. Our internal specifications guide our design methodologies if a customer is new to automation.

Every Farason machine is designed with the controls best suited for the application. Our Electrical department has designed equipment to some of the most challenging company specifications in the industry for fortune 500 companies

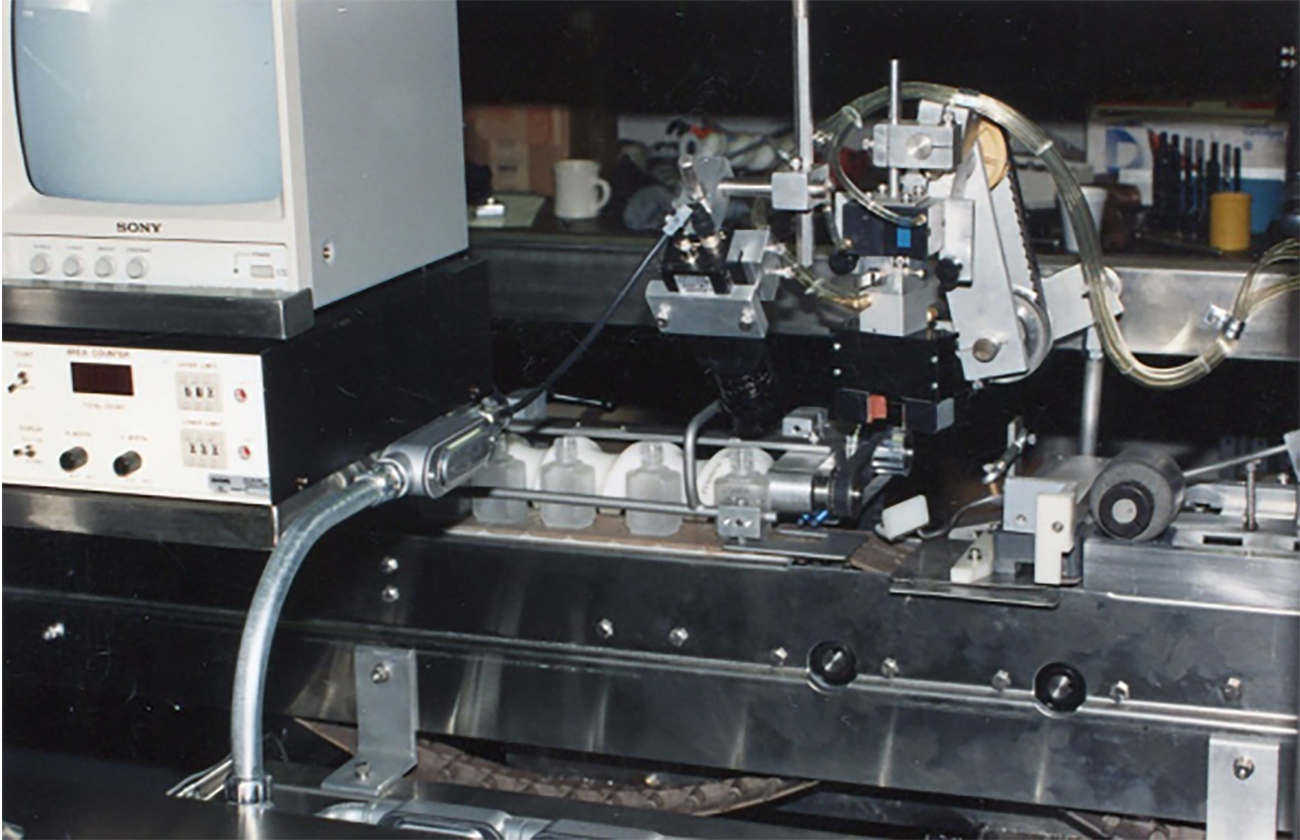

Farason designed and built its first piece of machinery in 1991, our first automated inspection in 1991, our first robot in 1993, our first vision guided robot in 1994 and in the following decades, we have been at the forefront of robotic integration technology. Since 1992 Farason has shipped over 900 machines to North America, Asia, South America and Europe.

Learn more

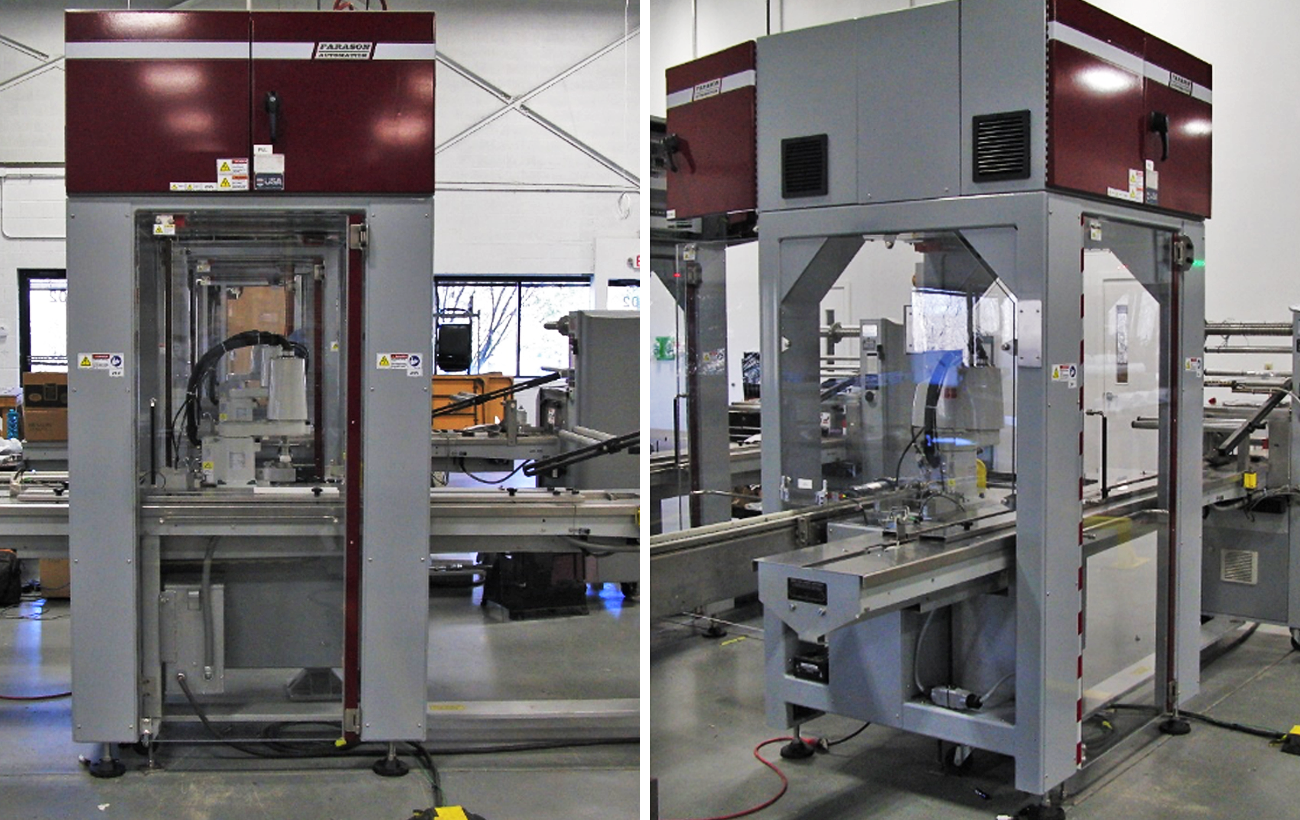

Every Farason machine is a completely custom piece of equipment designed to meet customer needs. We design, build, and program all of our machines on site. Our cutting edge R&D department ensures that Farason remains on the forefront of automation technology in ever constantly evolving industry.

Learn more

Farason's on-site R&D lab allows us to test the following: machine vision, flexible feeding solutions, machine fixtures, and robotic assembly. We also test our solutions with robotic simulations performed by our simulation department. All of our robotic projects are simulated prior to completion of their mechanical design. Payloads, inertias and rates are all processed to validate design and minimize risk.

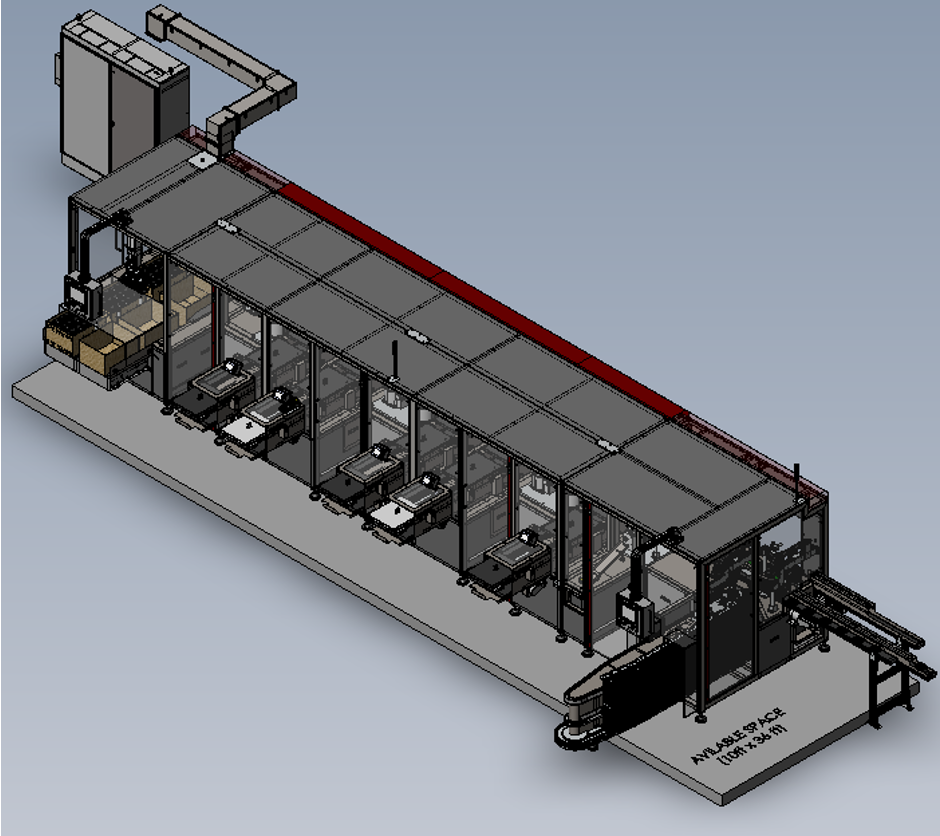

Our FaraCell consists of a welded, powder coated tubular frame, pushbutton stations, power disconnect, pneumatic disconnect, overhead electrical enclosures, light column, interlocked guard doors and sheet metal panels. FaraCells are configurable to the application at hand with configurations setups that range from single to quad cells. Main electrical routing pathways and wire baskets are between uprights and panels. Electrical enclosures are on top of the framework to maximize operator access inside the work cell. The FaraCell construct allows for rapid design and modular deployments

From make-up compacts to industrial sprinkler heads, Farason has handled materials and products from a vast array of industries. We have experience in the pharmaceuticals, cosmetics, food, consumer goods, and more. We are always looking to venture into new areas of product handling, and with our completely customized approach to every machine we are uniquely suited to do so.

ABB provides a comprehensive range of robots to help manufacturers improve productivity, product quality and worker safety. Regardless of application Fanuc has a robot to meet your needs. ABB has installed more than 400,000 robots worldwide and pioneer in automating industrial robots.

(Source: ABB Robotics)

FANUC has the robotics products and expertise to help you succeed. With more than 100 robot models and over 40 years of helping manufacturers achieve their production goals, we're ready for any manufacturing challenge in any industry. FANUC robots are easy to operate and provide complete flexibility.

(Source: Fanuc America)

Total ETO is an Engineer to Order ERP System with SolidWorks integration, procurement, parts tracking, and detailed job reporting. Total ETO leverages its team of technology experts, ERP professionals, and ETO business specialists work collaboratively with customers to meet their manufacturing needs.

(Source: Total ETO)

The best way to get an understanding of our work is to see them in motion. To see more videos of our machines click on the button below.

Watch More Videos Here